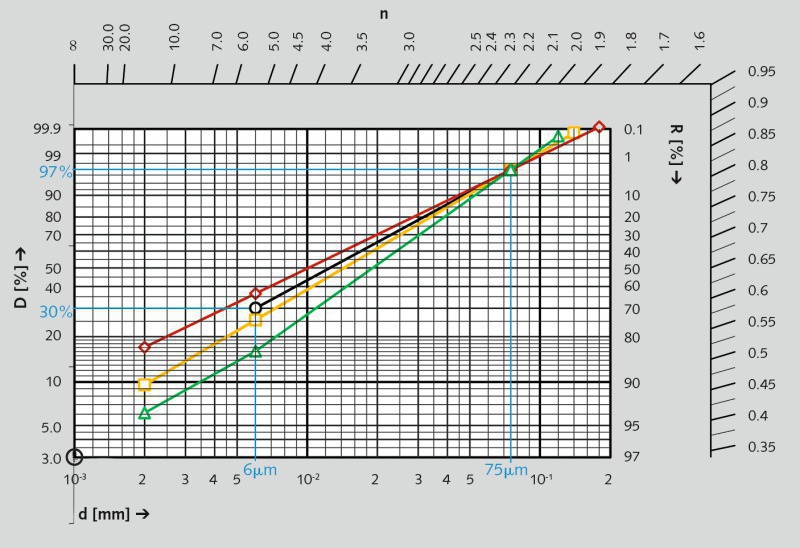

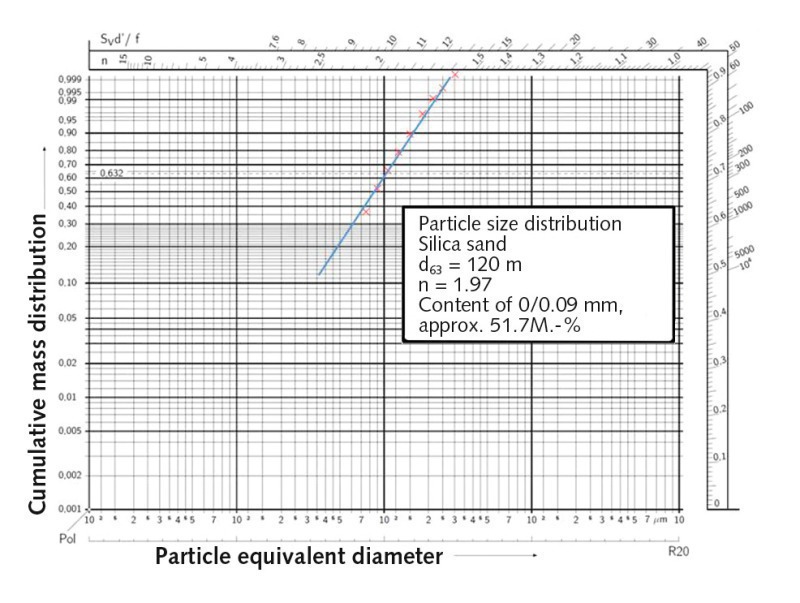

If you look at low D values right axis in the figure above, it looks like a plain log-scale because for D small ln 1-D is almost the same as D. Composites made from phenolic resin are filled with conductive filler mixtures containing copper powders, natural graphite powders and carbon fibers. At first sight it is easy to oversee the fact that the y axis is on a log-log scale rather than just a log-scale. Stir casting route has been adopted for the fabrication of aluminium matrix composite using Al-Si LM13 piston alloy. The results verify the calculation method of a solid mixture and show a linear dependence of the RRSB particle-parameter n on the concentration of matrix material SiC-content.

| Uploader: | Maugar |

| Date Added: | 11 March 2017 |

| File Size: | 59.43 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 94088 |

| Price: | Free* [*Free Regsitration Required] |

This entry was posted in ChemengUncategorized. However rrab electrical conductivity increases with the decreasing of copper particle size.

The present study aims to analyze the effect of particle size on nature of microstructural features and wear behavior of composite. The increased continuous conductive metal networks could be the main reason for the increasing of electrical conductivity as copper particle size decreases. This paper focuses on an iterative algorithm for setting and attaining particle packing densities by means of different concentrations of a matrix material. The grid is based on log vs.

The mechanical properties of a product, such as fracture toughness, bending strength and thermal conductivity are directly dependent on the amount of matrix material present.

The fluids viscosity influences the sedimentation velocity of particles.

The hardness decreases with the decreasing of copper particle size. Li 4 Ti 5 O 12 spinel-type anode materials were synthesized by high-energy ball milling and solid-state method using TiO 2 Nftz and Li 2 CO 3 as starting materials.

The grain size was 0. On the macroporous support a layer of fine powder fraction was deposited by gravitational sedimentation. The RRSB distribution is:.

In Microsoft Excel for example you have the function:. In non-German-speaking parts of the world and outside of the concrete and coal processing industries, the RRSB curve is more widely known as Weibull distribution.

If the sedimentary column is short, the turbulences created by adding the suspension of the dispersed powder in the sedimentary tube are more harmful. Fine size zircon sand particle reinforced composite exhibits better wear resistance than coarse particle at same weight percentage of reinforcement. Microstructural analysis shows that SiC has a pronounced effect on the microstructure and eutectic silicon refinement.

Neyz first sight it is easy to oversee the fact that the y axis is on a log-log scale rather than just a log-scale.

LIBPF blog The RRSB particle size distribution |

The analysis of the gradual porous layers was done using scanning electron microscopy and mercury porosimetry. Christian Edtmaier and Guillermo Requena. Composites made from phenolic resin are filled with conductive filler mixtures containing copper powders, natural graphite powders and carbon fibers. They are fabricated by compression molding technique.

Testing UI with UI scripting: The density, electrical conductivity and rrsg of composite are analyzed to determine the influence of copper particle size on the physical, electrical and mechanical properties of composite.

Materials Science Forum Volumes But the distance between the decades increases at values of D approaching 1, which hints at its log-log ntz. Indeed that can be rewritten: A tape cast friction layer was developed, in order to investigate the dependence of the parameters of the RRSB distribution on concentration of matrix material.

As a result, it would be suggested that the CMC was more effective dispersant reagent to produce the monodispersed and fine Cu powders with narrow size distribution using the wet chemical reduction process. The RRSB distribution is: Leave a Reply Cancel reply Your email address will not be published.

The Cu powders essentially were monodispersed and irregular in rrrsb regardless of reaction temperature and dispersant.

The RRSB particle size distribution

Stir casting route has been adopted rrsg the fabrication of aluminium matrix composite using Al-Si LM13 piston alloy. The particle size distributions was asymmetry and to be broad regardless of reaction temperature. The height of the column directly affects the quality of porous structure.

No comments:

Post a Comment